In some applications where 930 CV’s are stretched to the limits of their angle range you may need to “clock” the two CV’s with each other, perfectly on the splines. Cars that do not stretch the limits of a 930 CV past the recommended 26 degree range may not need CV clocking to work flawless, but it’s a good idea to clock them anyway, regardless of the max angle setup. If you’ve never clocked your CV’s and you’ve never had a problem, that’s because your car is designed within the 930 CV range limits, which is a good thing.

Clocking CV’s takes little effort, just the knowledge of how to clock them and the ability to remember to clock them when you’re reassembling your axles during your annual CV service. So clocking CVs is a good thing to do since it’s free, easy, and effective.

Annual service? Yes, to maximize the life of your CV’s you should remove and inspect them annually. Checking the ball bearings for wear, along with inner and outer bearing races of the inner star gear and outer case on an annual basis is advised. If you only go to the dunes a few times each year, inspect them every 15 trips to the dunes. This will minimize the risk of breakdown during your valuable duning time. It will also minimize the risk of ruining an axle caused from a broken star gear. Annual maintenance will reveal abnormal wear before it’s serious enough to break and mess up the axle splines.

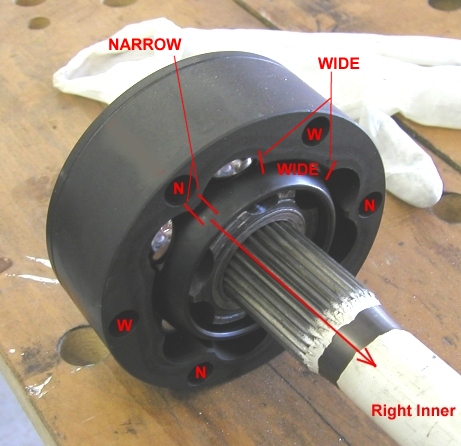

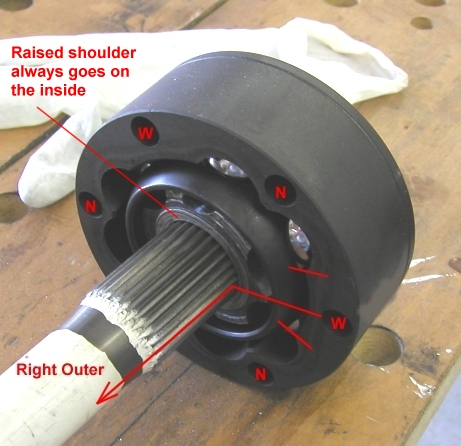

To clock your CV’s you must understand this simple rule of thumb, Wide aligns with Narrow. In this picture look at the outer case bolt holes. Each hole has a corresponding race wall width, or “gear width” as some folks call it. 3 of the holes have a WIDE width, the other 3 have a NARROW width. To align them properly look at the inside of each CV installed on the axle, viewed from the center of the axle. The objective is to align a WIDE race wall on one CV with a NARROW race wall on the other CV. “Wide aligns with Narrow”, as shown in these pictures.

In addition to “eye-balling” the alignment, to insure alignment of the CV’s on the splines, you could also buy a 3/8″ steel rod the length of your axle and insert it into one CV hole of each CVs after you think things are aligned. These holes are exactly 3/8″ ID. When the rod is installed there will be no question about alignment if the rod easily fits through and the CVs are square with the axle, assuming the N and W holes are aligned as illustrated. When the rod is installed, both CVs must be square with the axle, perpendicular. If they aren’t, you’re likely not aligned, possibly off by one spline.

These two pictures depict the right axle assembly. The left side would look the same.

N aligns with W below as shown in pictures with arrows.

Both CV’s are the same so it doesn’t matter which one goes on each end of the axle, but it does matter which side you reinstall a used axle. Always install the axles on the same side as it was originally installed to keep the twist pattern of the axle in the same direction.

Axle Orientation

When servicing your CVs it’s very important to install your axles on the same side as they were previously used when reassembling. So before you start yanking out the CV bolts, use a felt marker and mark each axle:

RIGHT and LEFT Comprendo?

If you orient the axles identical to how they were removed this will insure the twist pattern of the axles will be in the same direction as they were originally “broken in”. If you fail to install them on the correct side, and reverse the twist pattern of the axle, this can weaken it, possibly inducing failure. And if you don’t think axles twist, take a look at the chipped powder coat of this axle near the splines in these pictures. Yes, they twist, and they set a “twist pattern” from the first day of use.

Some folks are also anal about keeping the axle orientation on each side the same, which isn’t a bad idea. But if you have the right side axle on the right side, flipping end to end doesn’t reverse the twist. But some folks believe the twist may be different since power is delivered from the transaxle side. Whether or not axle orientation (flipping ends) on the same side makes a difference is a good discussion to have around the campfire at 1am. 🙂

Don’t forget to label the axle side BEFORE disassembly. The felt markings can be removed later with lacquer thinner, or simply mark them in the area UNDER the CV boot so it won’t show when reassembled.

DO NOT mark the axles with an engraving tool !! BAD idea.